In today’s tech-driven world, it’s no surprise that technology is becoming increasingly influential in all business operations. One area where technology should not be overlooked is machinery efficiency. With the right strategies for leveraging technology, businesses can significantly improve the performance and productivity of their machinery. Here are some ways you can use technology to maximize your machinery efficiency.

Integrating Automation

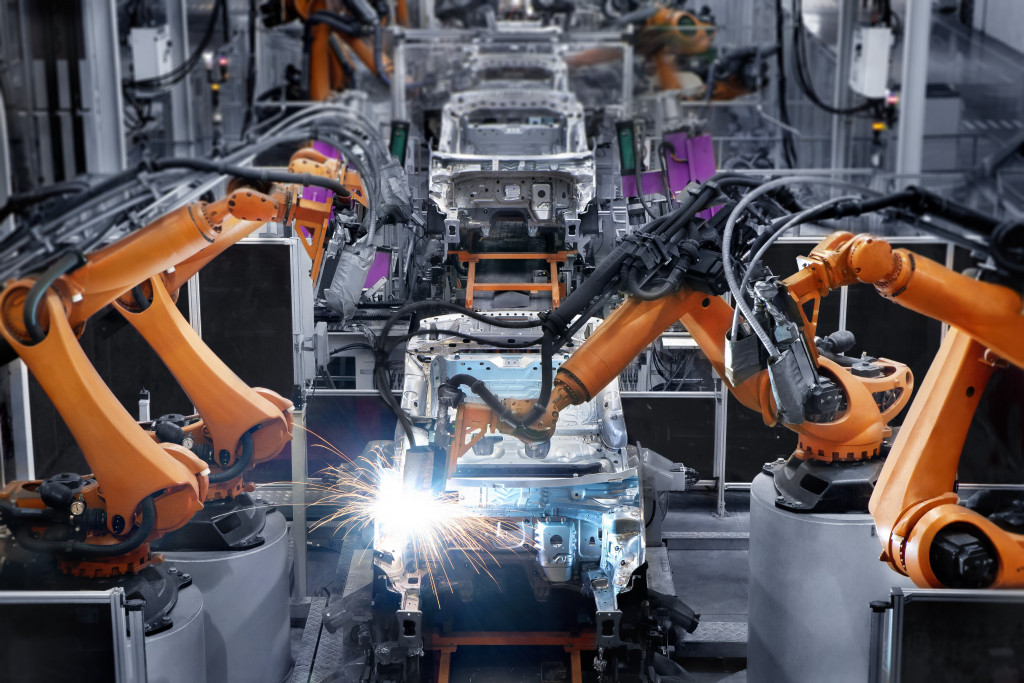

Many businesses are taking advantage of automation to increase their machinery efficiency. Automation involves using machines and computers to control certain processes without human intervention.

Automation means faster production times, reduced errors, greater accuracy, and improved safety conditions for employees. For example, a bakery could automate its mixing process with a robotic arm so that the dough is mixed more evenly and quickly than with manual labor alone. Additionally, automation helps reduce costs associated with labor and material usage while increasing overall throughput speeds.

Automation can be used in a variety of industries, from manufacturing and industrial processes to healthcare systems. Integrating automation into existing systems requires thoughtful planning and execution and training for employees who will operate the automated machinery. As businesses become increasingly tech-savvy and look for ways to improve their efficiency, the integration of automation will continue to grow in popularity. With proper planning and execution, businesses can benefit from the increased efficiency of automation while maintaining a competitive edge in their market.

Additionally, automation requires a well-thought-out design and plan for how it will integrate with existing processes and systems to ensure smooth operation. Finally, businesses must train their employees on how to properly use automated machinery to maximize its potential while minimizing any associated risks.

Implementing Predictive Maintenance

Predictive maintenance is another way businesses can use technology to maximize their machinery efficiency. Predictive maintenance involves collecting data from equipment sensors over time to identify potential issues before they become serious problems. These problems can cause costly downtime or damage to other components.

This data-driven approach allows companies to anticipate mechanical problems before they occur, helping them avoid expensive repairs or replacements down the line. For example, predictive maintenance could detect abnormal vibrations in a motor before it fails. This eliminates unnecessary downtime and reduces repair costs by catching the problem before it worsens.

Aside from predictive maintenance, businesses can also integrate modern technologies into their equipment. For instance, they can install a reliable electric motor gearbox to enhance precision in speed changes and minimize vibration when using the machinery. The equipment can also reduce the noise produced by the engine. Using the equipment can ensure the machinery runs smoothly.

Overall, technology can play a crucial role in maximizing the efficiency and performance of all types of machinery.

Analyzing Machine Performance

Analyzing machine performance through technology is also crucial for improving machinery efficiency. Using sensors and data collection tools, businesses can monitor their machines in real-time and track key performance metrics like uptime and throughput speed over time. The information helps managers understand how each machine is used at any moment. This gives them insight into which areas may need more attention or resources to maximize efficiency levels across the entire operation. For example, suppose a manager notices that one machine has been running slower than usual over the past week or two. In that case, they can take steps to investigate further and make adjustments as needed to improve its performance going forward. In addition, analyzing machine performance allows businesses to pinpoint areas where they may save time and money through improvements in efficiency or production.

Analyzing machine performance is also crucial for ensuring the safe operation of machinery and reducing the risk of accidents or breakdowns. With access to data from sensors, managers can look for signs of wear and tear, overheating, or other potential problems that could lead to a breakdown. By monitoring these signs and taking the necessary steps to address any issues quickly, businesses can reduce the risk of accidents or unsafe operations. Additionally, analyzing machine performance can help organizations identify ways to make their processes more efficient and reliable to ensure the successful completion of projects.

Ultimately, taking the time to analyze machine performance is essential for any organization that wants to get the most out of its machinery. With access to detailed data and metrics, managers can make informed decisions on how best to utilize their resources and ensure that machines run as efficiently as possible.

Technology provides an invaluable tool for optimizing machinery efficiency across many different businesses, from bakeries to manufacturing facilities. It helps organizations improve their bottom lines by reducing labor, materials, and downtime costs due to mechanical failure or malfunctioning equipment. By following these tips, businesses can ensure that their machinery runs at peak levels of efficiency all year long. A little investment in technology now could provide significant returns down the road.